- Apparel

- Accessories - Dress Up

- Axle Dress Up Kits - Frame Plugs

- BAR ENDS HANDLE WEIGHTS

- BELLY PANS LOWER WING

- BRAKE BAR TORQUE LINK

- CALIPER BLOCK OFF DELETE CAPS

- CHAIN GUARD SIDE COVER

- GAS CAP - FUEL CAPS

- GRIPS - SPORTBIKE, V-TWIN, METRIC CRUISER

- GSX-R GSXR PARTS ACCESSORIES

- Exhaust

- EXHAUST HANGER PEG PLUG

- FORK TUBE CAPS

- FRAME SLIDERS & CRASH PROTECTORS

- GAUGE PANEL COVERS

- HAYABUSA PARTS ACCESSORIES

- HEEL GUARDS - KICK PLATES

- IGNITION SWITCH KEY COVERS

- KICKSTANDS - SIDE STAND

- License Plate "Tag" Frames and Accessories

-

License Plate Relocating Solutions Brackets Tag Relocators

-

Chain Guard License Plate Tag Relocator Bracket

- Chain Guard License Plate Tag Relocator For Honda

- Chain Guard License Plate Tag Relocator For Kawasaki

- Chain Guard License Plate Tag Relocator For Suzuki

- Chain Guard Licnese Plate Tag Relocator For Yamaha

- Chain Guard License Plate Tag Relocator For "Trac Dynamics" Swingarms or Universal Applications

- LICENSE PLATE FENDER ELIMINATOR TAG BRACKET

- SWINGARM HORIZONTAL VERTICAL LICENSE PLATE TAG RELOCATOR

- PASSENGER EXHAUST HANGER LICENSE PLATE RELOCATOR BRACKET

- SWINGARM CURVED VERTICAL LICENSE PLATE TAG RELOCATOR

-

Chain Guard License Plate Tag Relocator Bracket

- Lowering Links / Drop Kits

- Master Cylinder Reservoir Cap

- Mirrors - Billet

- MIRROR BLOCK OFFS DELETE CAPS PLATES

- OIL FILL CAPS

- Pre-Load Adjusters

- RC CARS AND PARTS

- Rotors / Braking

-

Spike, Flat Screws, Logo Screws, Hardware

- CONE SPIKE SCREWS

- HELIX SPIKE SCREWS

- SPIKED SPIKE SCREWS

- GROOVED SCREWS

- GROOVED & SPIKED "WEB" SCREWS

- DOMED SCREWS

- DOMED & SCALLOPED SCREWS

- FLAT SCREWS

- FLAT SCALLOP SCREWS

- ONYX ICED SMOOTH SCREWS

- ONYX ICED SCALLOP SCREWS

- WHITE ICED SMOOTH SCREWS

- WHITE ICED SCALLOP SCREWS

- CLEAR "ICE" CONE WINDSREEN FAIRING SCREWS

- CLEAR "ICE" HELIX WINDSREEN FAIRING SCREWS

- CLEAR "ICE" SPIKE WINDSREEN FAIRING SCREWS

- HAYABUSA SEAT BOLTS SCREWS

- GSXR SEAT BOLTS SCREWS

- HAYABUSA CARGO NET TAIL BOLTS

- FLAT LOGO SCREWS

- FLAT SCALLOP LOGO SCREWS

- WASHERS FOR FAIRING BODY WINDSCREEN SCREWS

- DOMED HEX KEY SCREWS

- DOMED & SCALLOPED HEX SCREWS

- FLAT HEX SCREWS

- FLAT SCALLOPED HEX SCREWS

- LICENSE PLATE SCREWS HARDWARE

- STEM YOKE PLUG

- Swingarm Spools / Sliders

- Top Clamps

- Top Clamp Tree Covers

- V-Twin, Harley, Chopper, Bobber

- Valve Stem Caps

- ZX-14 ZX-14R PARTS ACCESSORIES

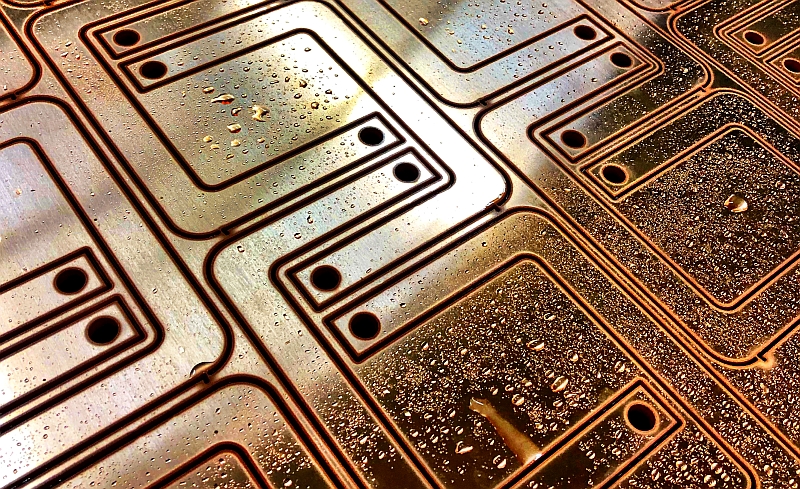

Waterjet Cutting

JDA Custom Inc Manufacturing - Waterjet Cutting serving Chicagoland

Located on the Southside of Chicago JDA Custom Inc has been using CNC waterjets since 1996. Water jet cutting is not a new technology for all but not everyone knows the full potential and advantages of the ability to cut with water. The addition of abrasives to concentrated high pressure water give us the ability to cut a wide range of materials.

Being one of the pioneers of waterjet cutting in Chicago, JDA Custom has cut material from paper books, to stainless steel 9.5" thick. Our cutting capabilities are 72"x 120" but are not limited to that as our innovations and ingenuity allows us to adapt to what ever is thrown at us.

Abrasive Waterjet Cutting does not have heat affected zones and will not work harden materials like a laser or plasma torch will. Being able to cut a wide array of materials ferrous and non ferrous metals, alloys, hardened or annealed makes our process a great choice to create a finished product or even a rough out for other machine shop to complete their job. JDA Custom Inc also has a full machine shop with 4-axis mills and lathes where we can do secondary work to your cutouts.

Water Only Cutting is great when cutting gaskets, shims, foam and other parts or shapes that are delicate and do not require abrasives. Gaskets and foam cutting are very popular at JDA Custom with our water only process. We specialize in low to high volume runs which help many companies develop their product line or maintain their inventory with what they need.